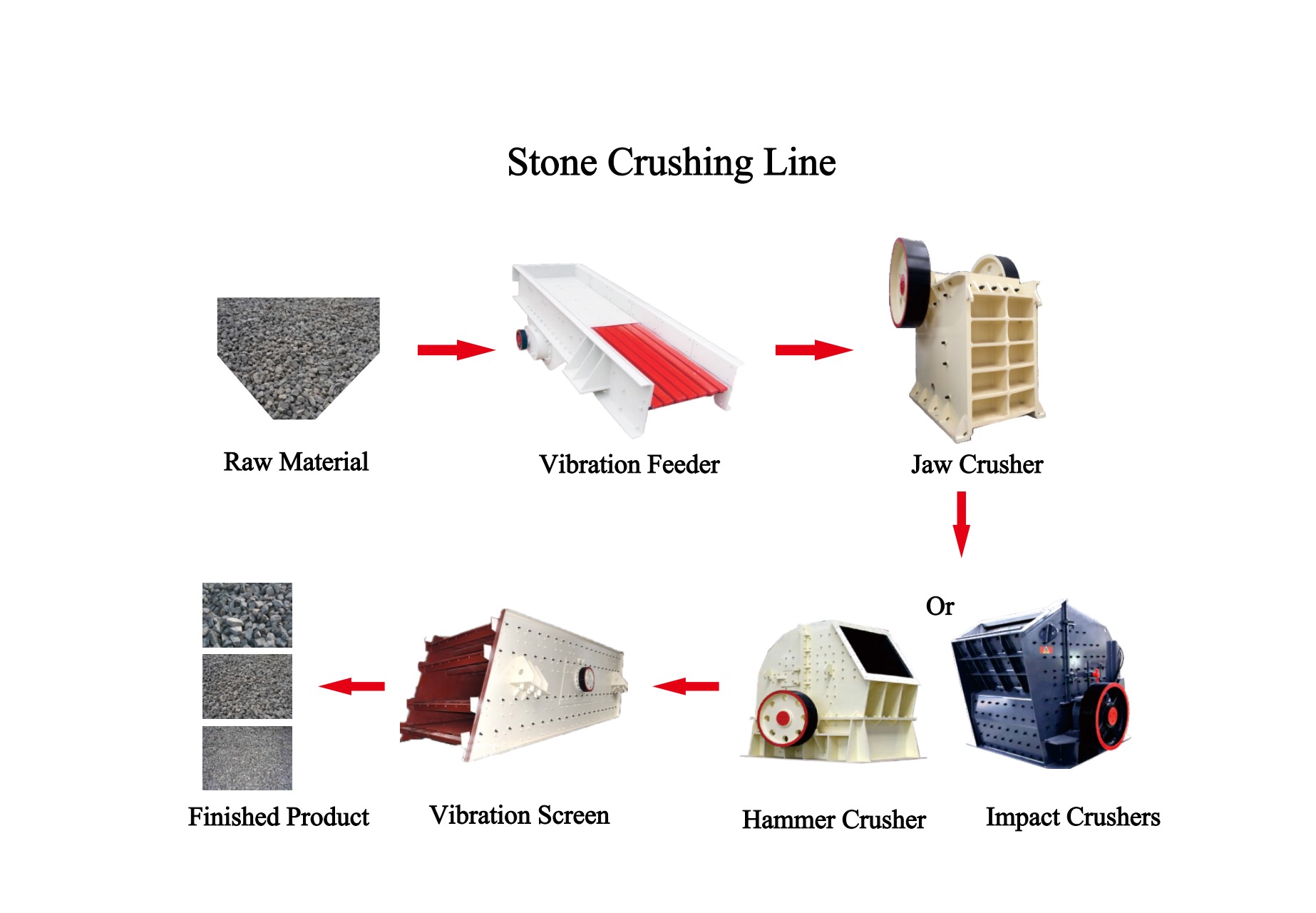

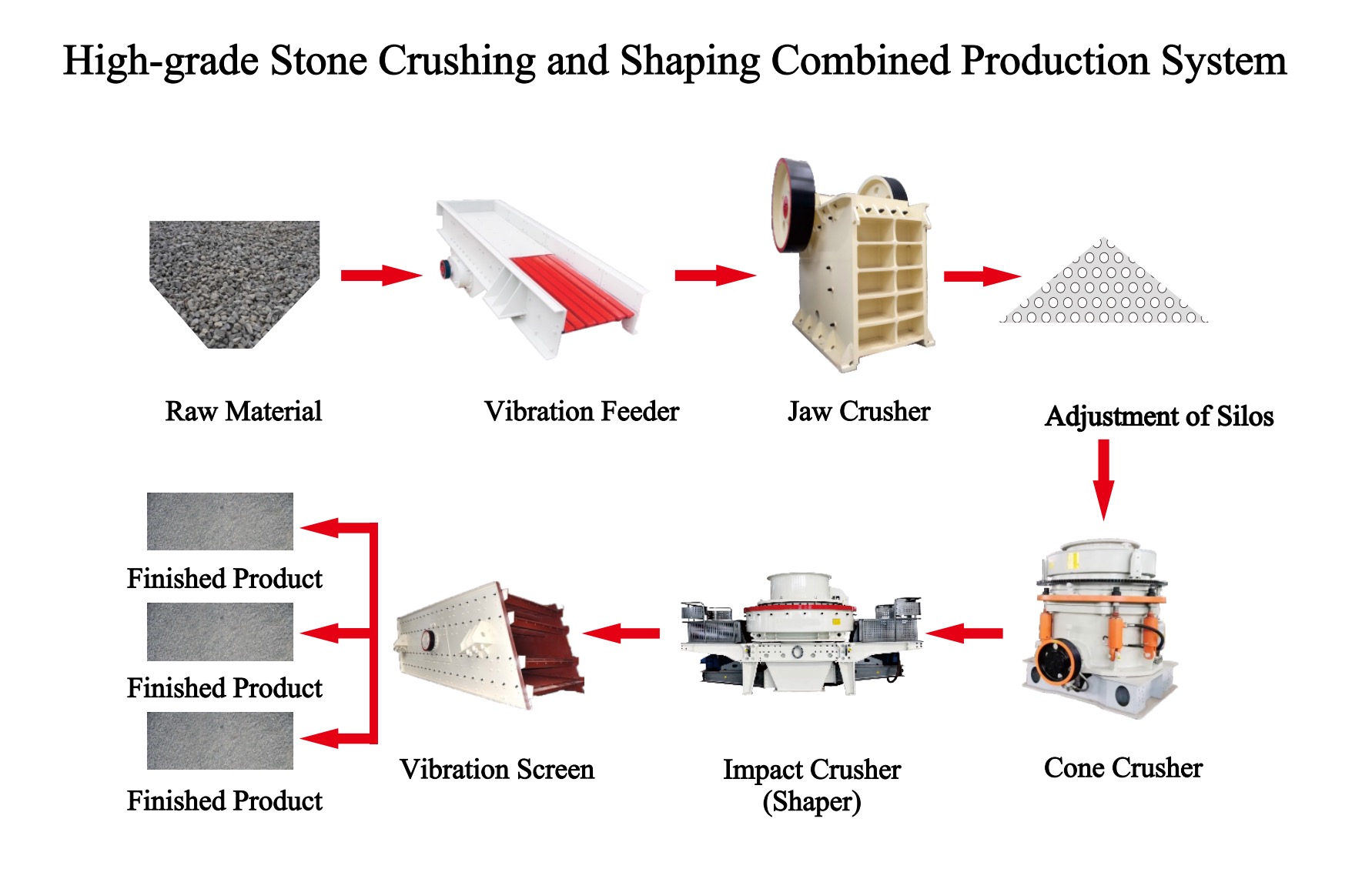

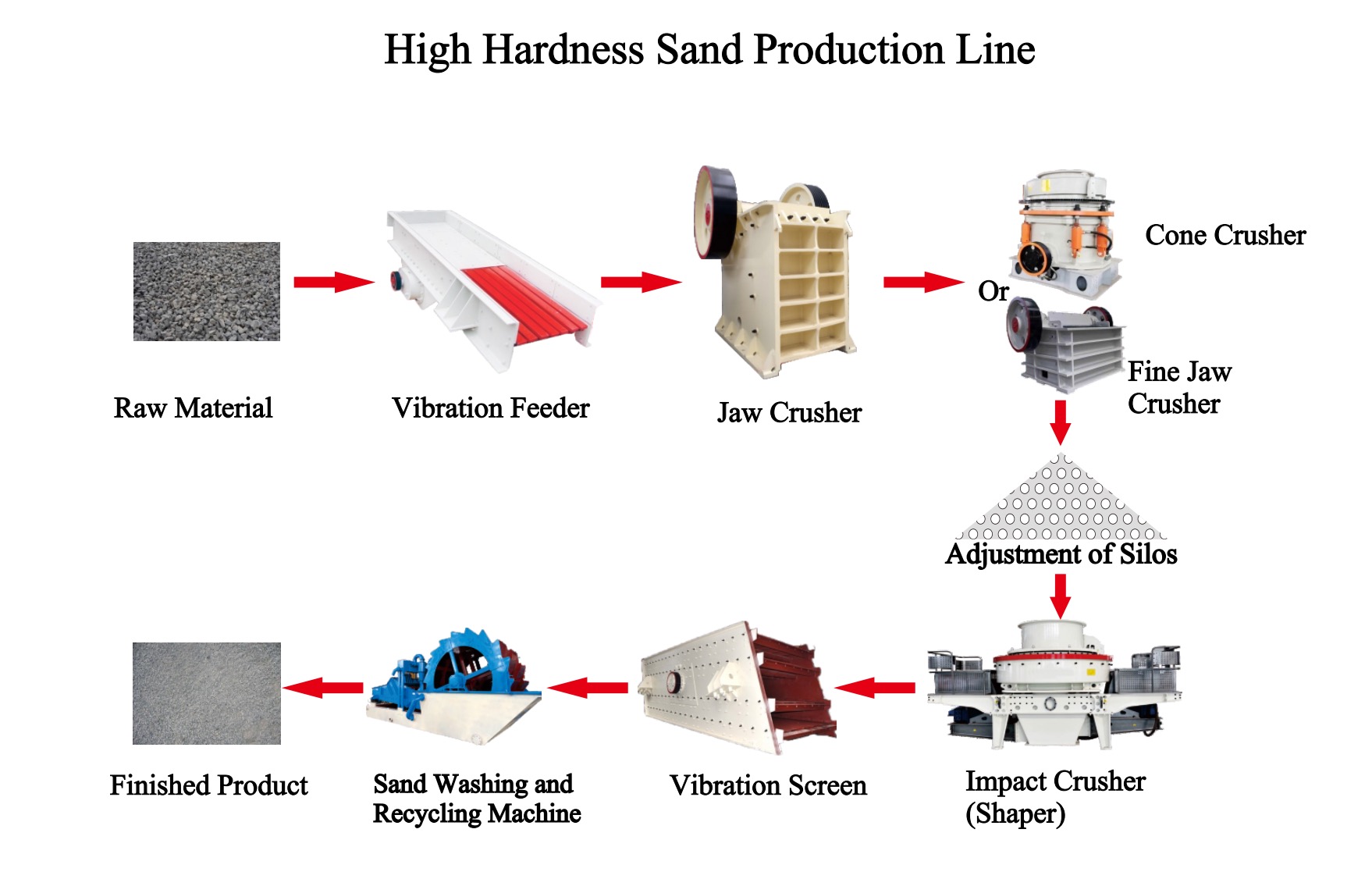

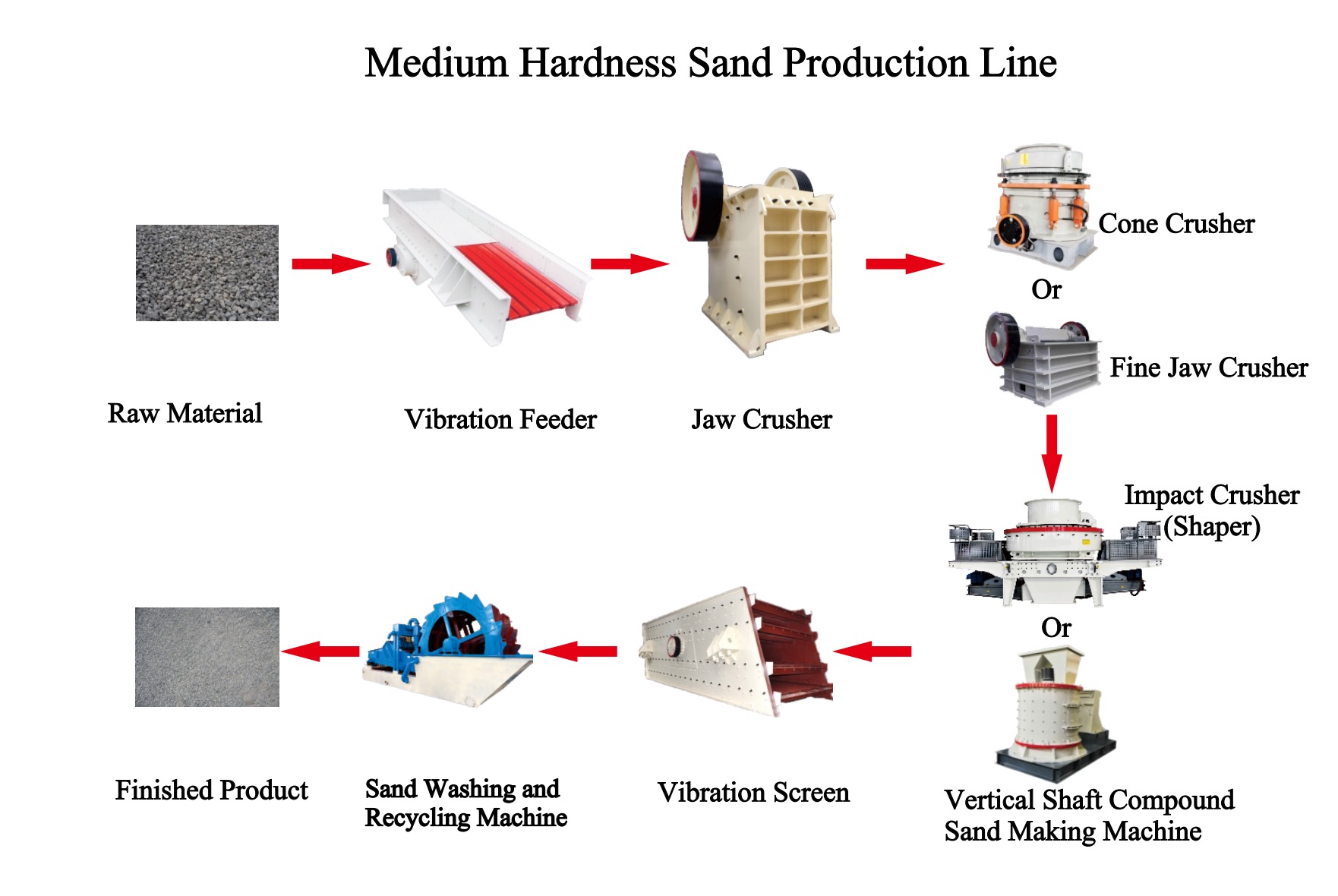

Crushers

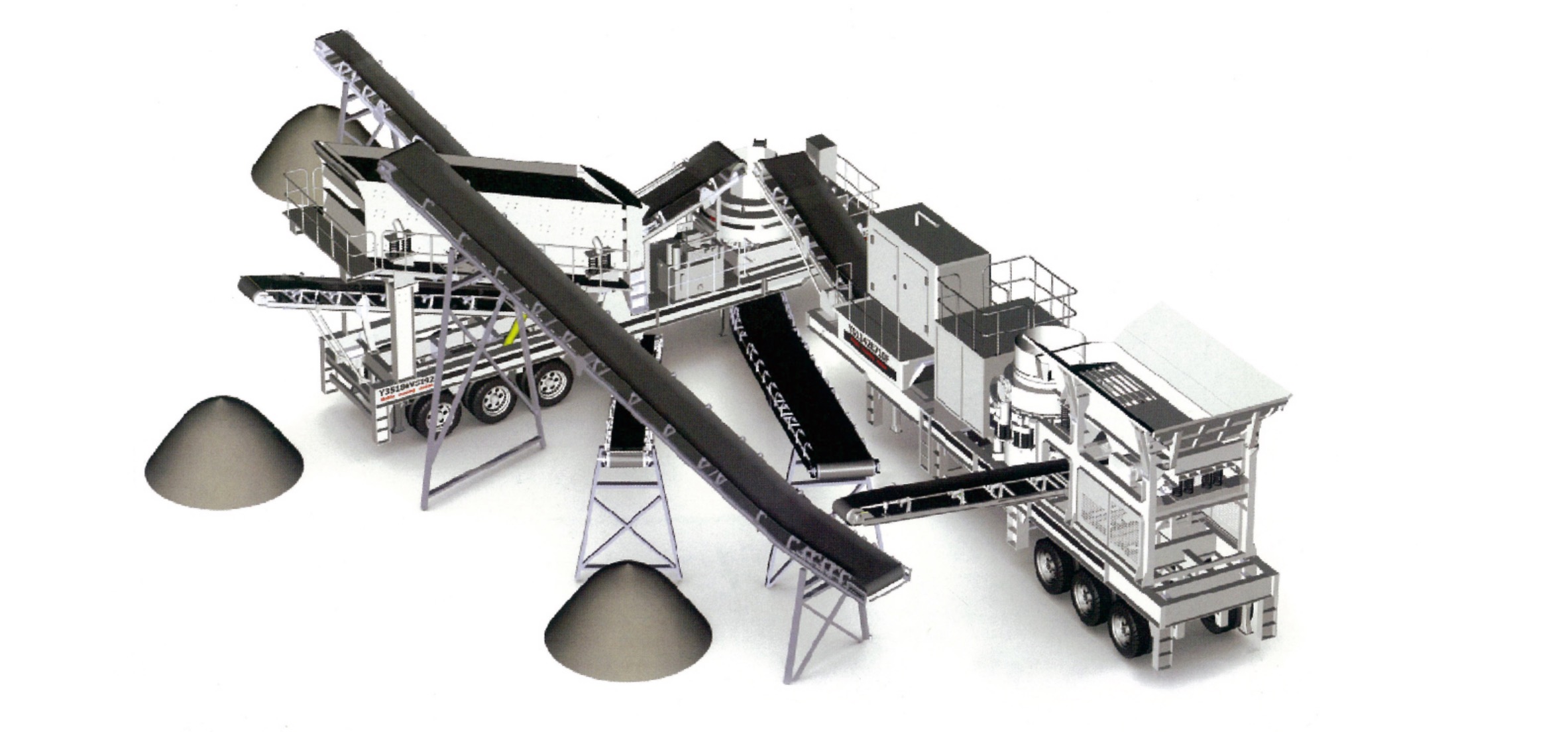

Multisegment combination example

Note: we can flexibly configure primary crushing, secondary crushing and tertiary crushing according to different requirements of different customers, and optimize the combination of crushing and screening at all levels. We will try our best to meet the requirements of customers.

MOBILE CRUSHING STATION

--Jaw Crusher Sieving Combination Station--

Brief introduction

It is widely used in construction waste disposal and construction waste crushing. Construction of highways and railways; Large engineering projects such as hydropower stations use crushing equipment. Road and bridge construction, urban construction, metallurgy, energy and other departments, the crushing, screening and other operations. The following main features: high performance PE series of jaw crusher, and high-performance vibrating screen, belt conveyor, crusher integration of belt conveyor, crusher integration vehicle installation, vehicular integration of motor and control box.

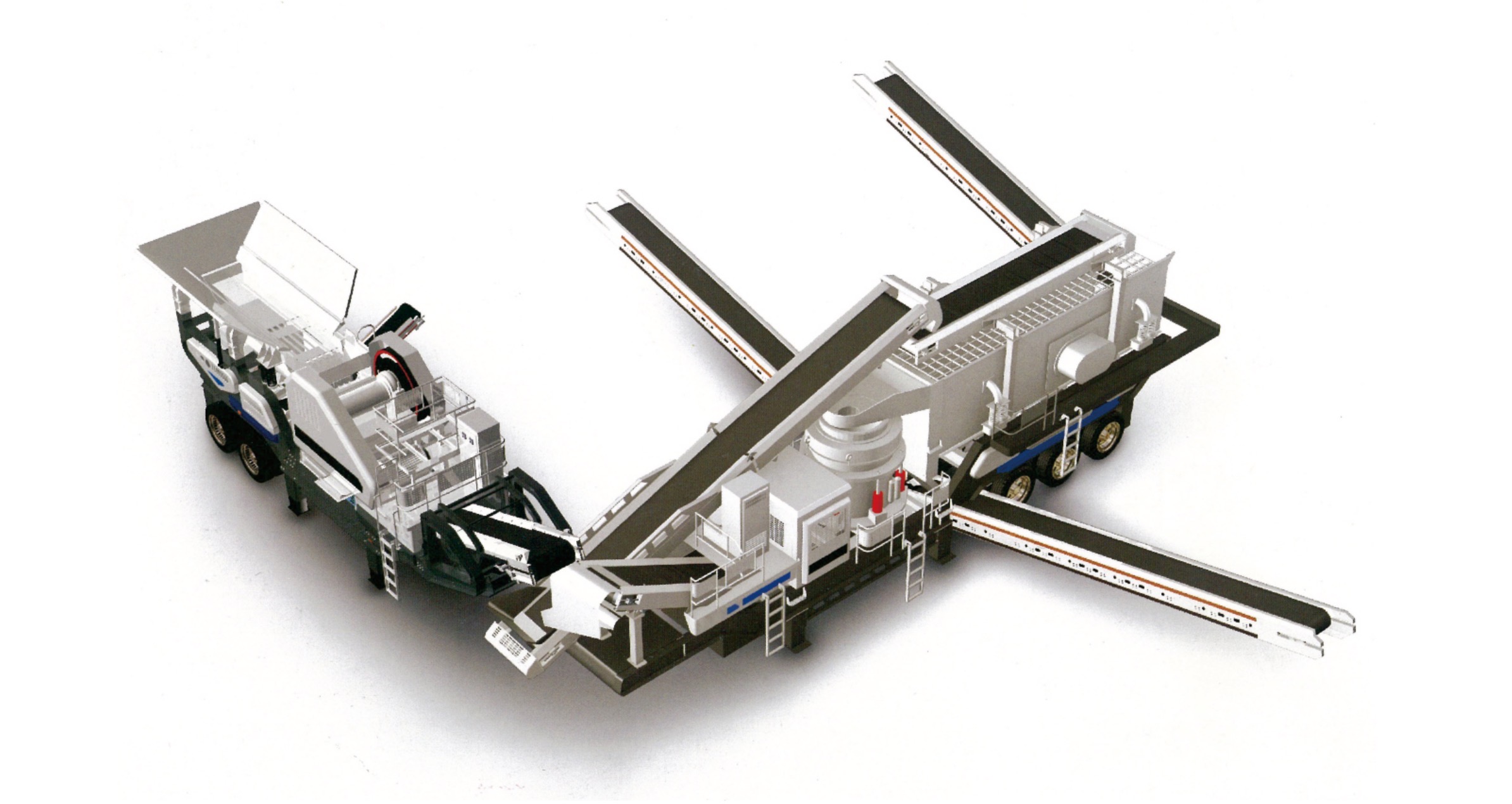

--Tyred Counter Attack Broken Mobile Crushing Station--

Brief introduction

Tyred counter attack broken mobile crushing station is mainly used in metallurgy,chemical industry,building materials,water and electricity often require relocation homework materials such as processing,especially used in highway,railway,water and electricity engineering and other iquidity stone homework.Users can usevariousconfigurations according tothetype of raw materials,size and the requirements of finished materials.In particular,itis suitable for the small rushing site,suitable for construction waste disposal,and the crushing of construction waste.

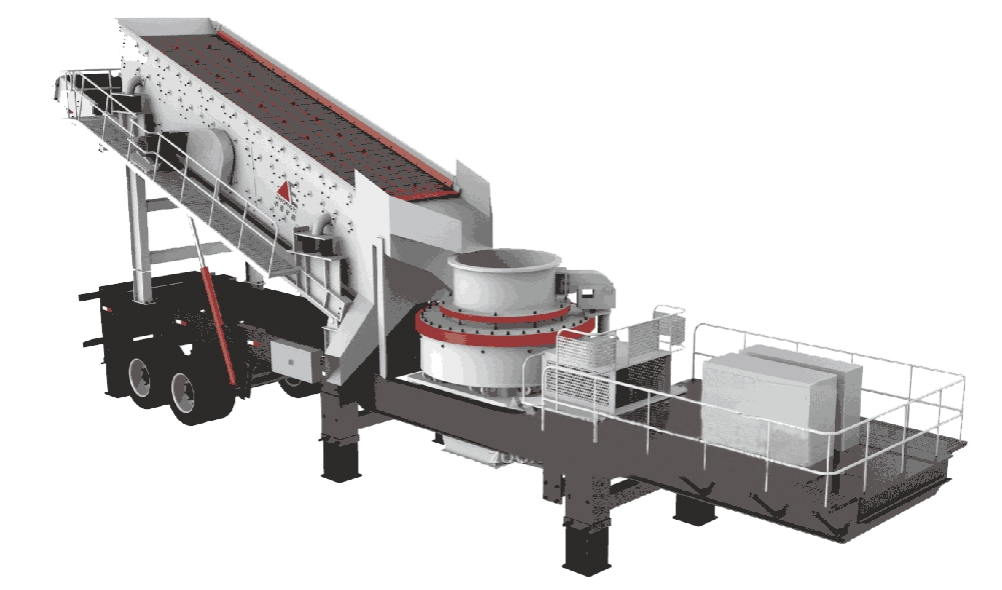

--Vertical Shaft Impact Crusher Mobile Crushing Station--

Brief introduction

It is widely used in road and bridge construction, urban construction, metallurgy, energy, etc., for crushing and screening. It is characterized by large processing capacity, fine grinding, high efficiency, economy, strong adaptability, crushing and screening, self-loading conveyor and so on.

--Multi-dimensional Integrated Coarse and Fine Secondary Mobile Crushing Station--

Brief introduction

Economical and multi-integration suitable for smalland medium-sized customers. The coarse and fine secondary crusher has reasonable structure, flexiblerotary and small covering area.

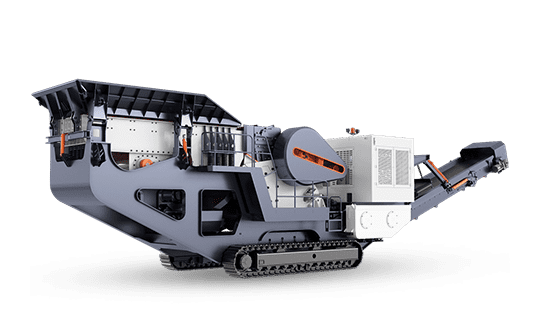

Crawler Mobile Crushing Station Series

Crawler mobile crushing station is a kind of high efficiency crushing equipment, which adopts self-drive mode,advanced technology and complete functions. The equipment can reach any location of the work site under any terrain conditions. This can reduce the handling of materials and facilitate the coordination of all auxiliary machinery and equipment. The crawler mobile crushing station has a large crushing ratio, and its optimized design can meet the most needed technical characteristics of the crusher, with high productivity and uniform granularity of finished products.

--Crawler type mobile jaw crushing plant--

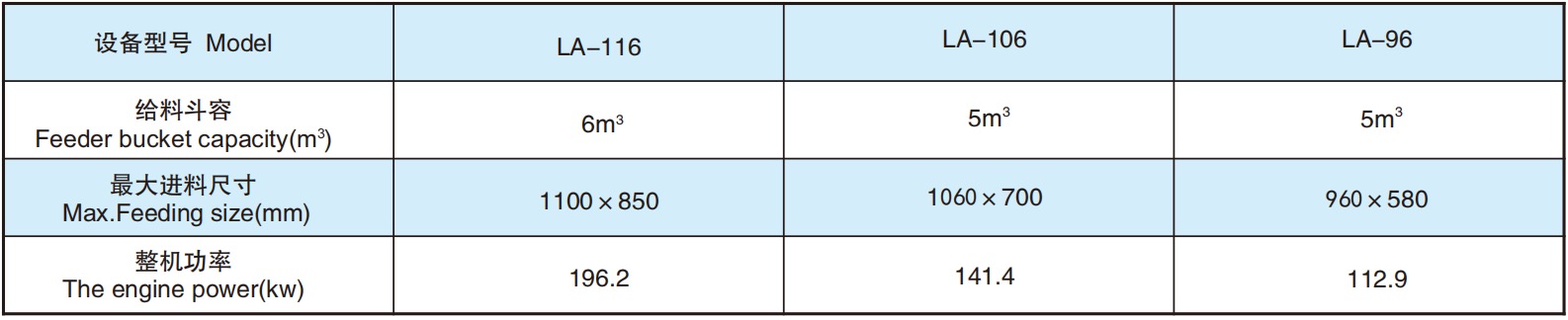

Specifications and performance parameters

--Crawler type mobile heavy-duty hammer crushing plant--

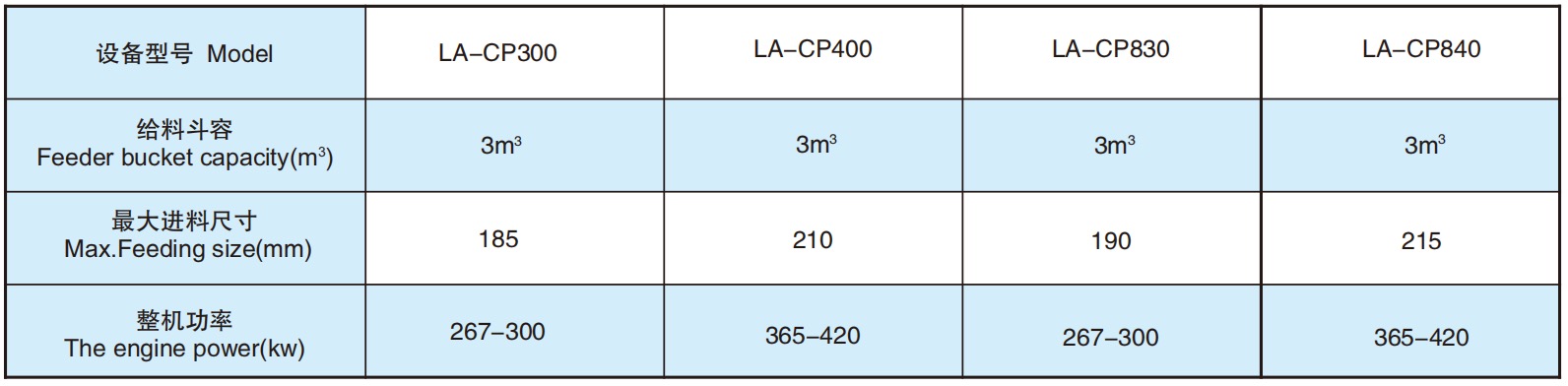

Specifications and performance parameters

--Crawler type mobile screening plant--

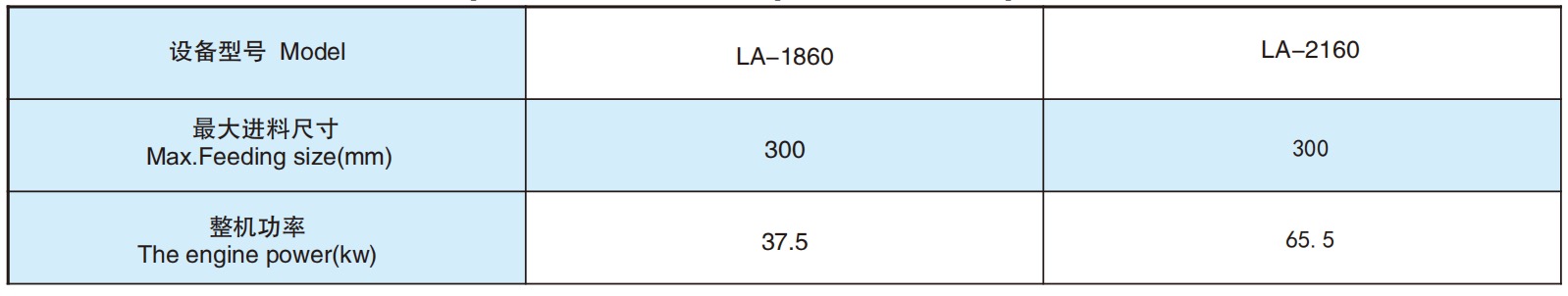

Specifications and performance parameters

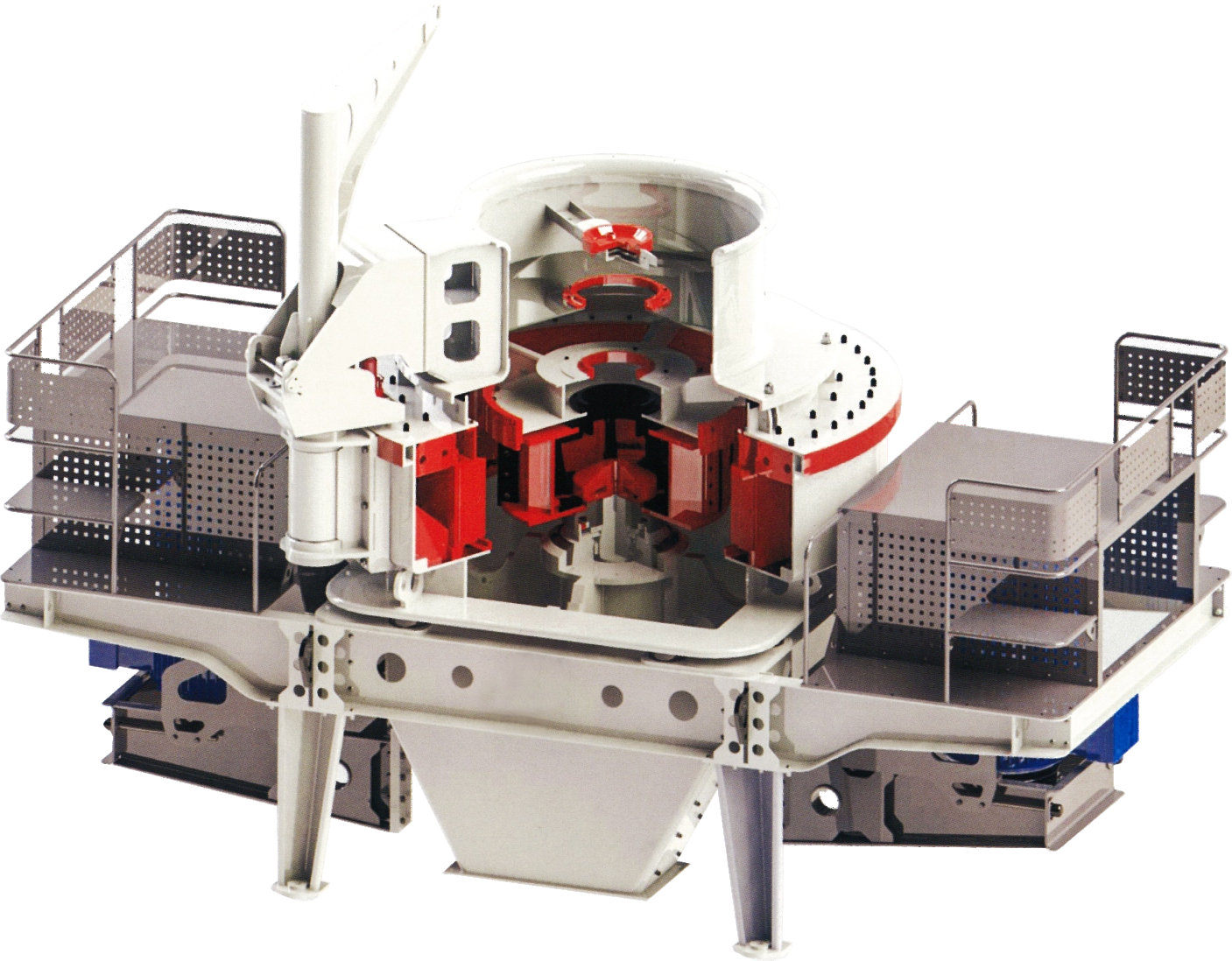

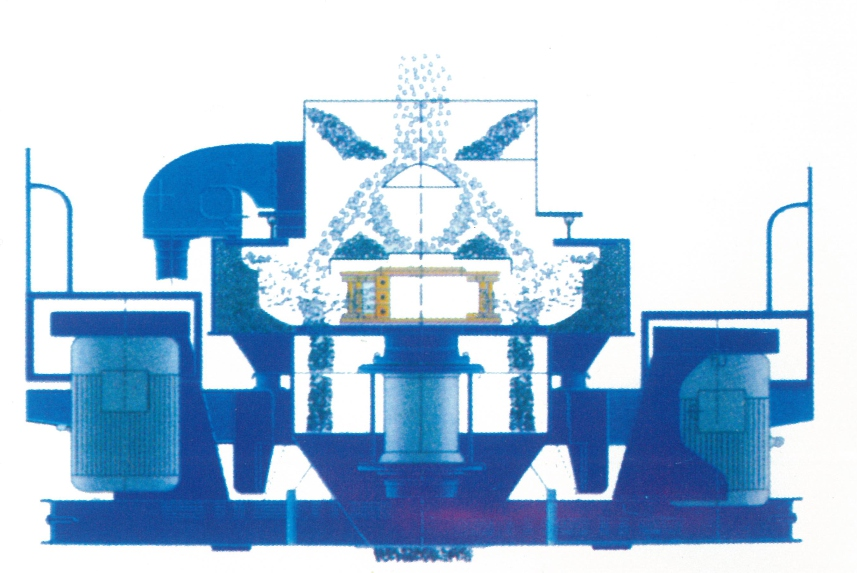

VSI6X Series High Efficiency Vertical Shaft Impact Crusher

Performance Characteristics

The impeller structure adopts the new four throwing port design to improve the material throughput, compared with three impellers of the same material crushing efficiency increased by about 20%.

The transmission part of the equipment adopts special sealing structure to prevent oil leakage from the bearing barrel. The bearings are imported to minimize thefailure of the rotating system.New lifting device is added to facilitate the maintenance of the equipment. The simple design of the lower part of the machine body effectively prevents the blockage

of the lower part of the machine body when the water content of the material is too large.

Adopting the working mode of “stone hitting stone” to reduce the use of wear-resistant types and lower the production cost of customers.

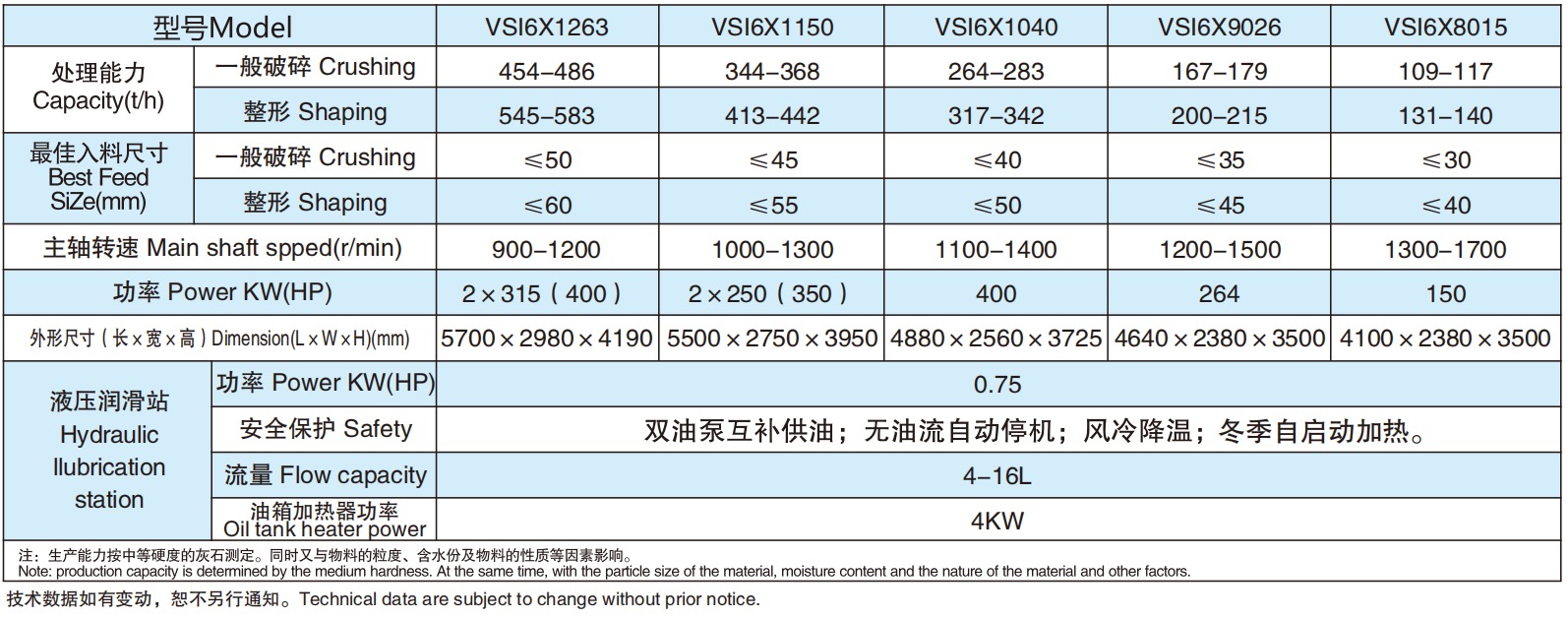

Specifications and performance parameters

5X Series High Efficiency Centrifugal Impact Crusher

5X series of high efficiency centrifugal impact crusher is our company introduced Germany's latest technology, at the same time has a number of independent patent rights of the latest generation of products, it is a perfect combination of professional crushing technology and mechanical manufacturing model,Is the full embodiment of new technology and new technology. It can not only provide the best quality sand and gravel for the highway, high-speed railway, high-rise building, municipal engineering, hydropower dam construction, port and whart, concrete mixing station, etc.

Aggregate, indisputably become the core equipment of sand industry and stone plastic field; and increasingly become the mainstream equipment of metal ore, quartz sand, slag processing etc.. 5X series highlmpact crusher is a new and high efficiency crushing machine in the world

Main performance characteristics

It has the following unique features and advantages

1, deep cavity type rotor after optimized design, so that the material throughput increased by about 30%. 2, peripheral guard plate partial wear can be used up and down the head, improve the utilization of materials, can improve the service life of more than 48%. Wear-resistant block combined design, only need to change the wear part, can reduce the use of more than 30% of the cost.

3, the most core wear-resistant materials used in the United States important industry with highly wear-resistant high-temperature materials.

4, the use of diamond-shaped impact block, to avoid damage to the vertical plate after the material impact wear.

5, the optimal launching mouth and internal more smooth curve-shaped design, reduce the resistance of the flow of materials, greatly improving the material throughput capacity.

6、Dual-use bulk material plate, easy to operate, to realize the two feeding methods convenient conversion.

Special sealing structure at the lower end of the main shaft ensures no oil leakage even without oil seal.

8, the use of original imported fittings of the hydraulic cover opening device, can be convenient and fast moving cover, so that the replacement and maintenance of the internal parts of the body to save labor and effort. 9,: Selection of high protection level of the motor. This type of motor is characterized by high efficiency and low noise. In line with the International Electrotechnical Commission (IEC) standards, F-class insulation, IP54/55 protection level.

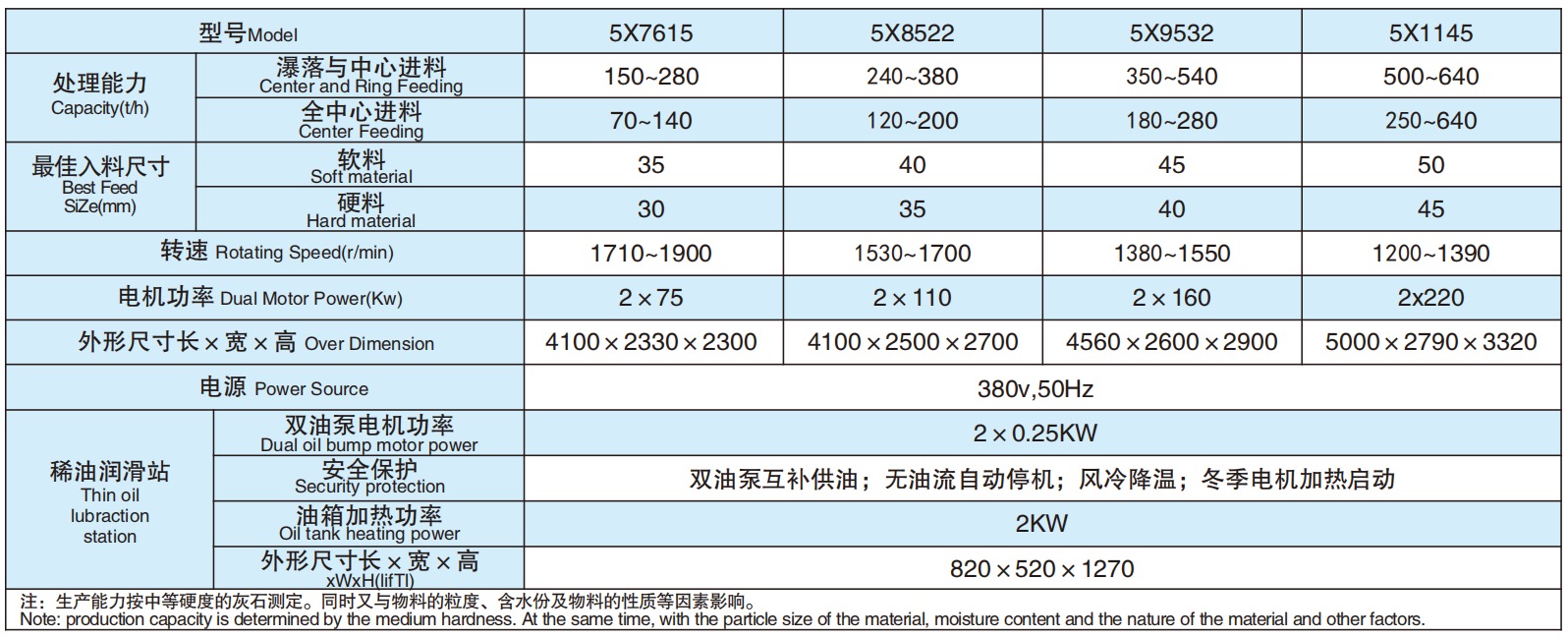

Specifications and performance parameters

Specifications and performance parameters

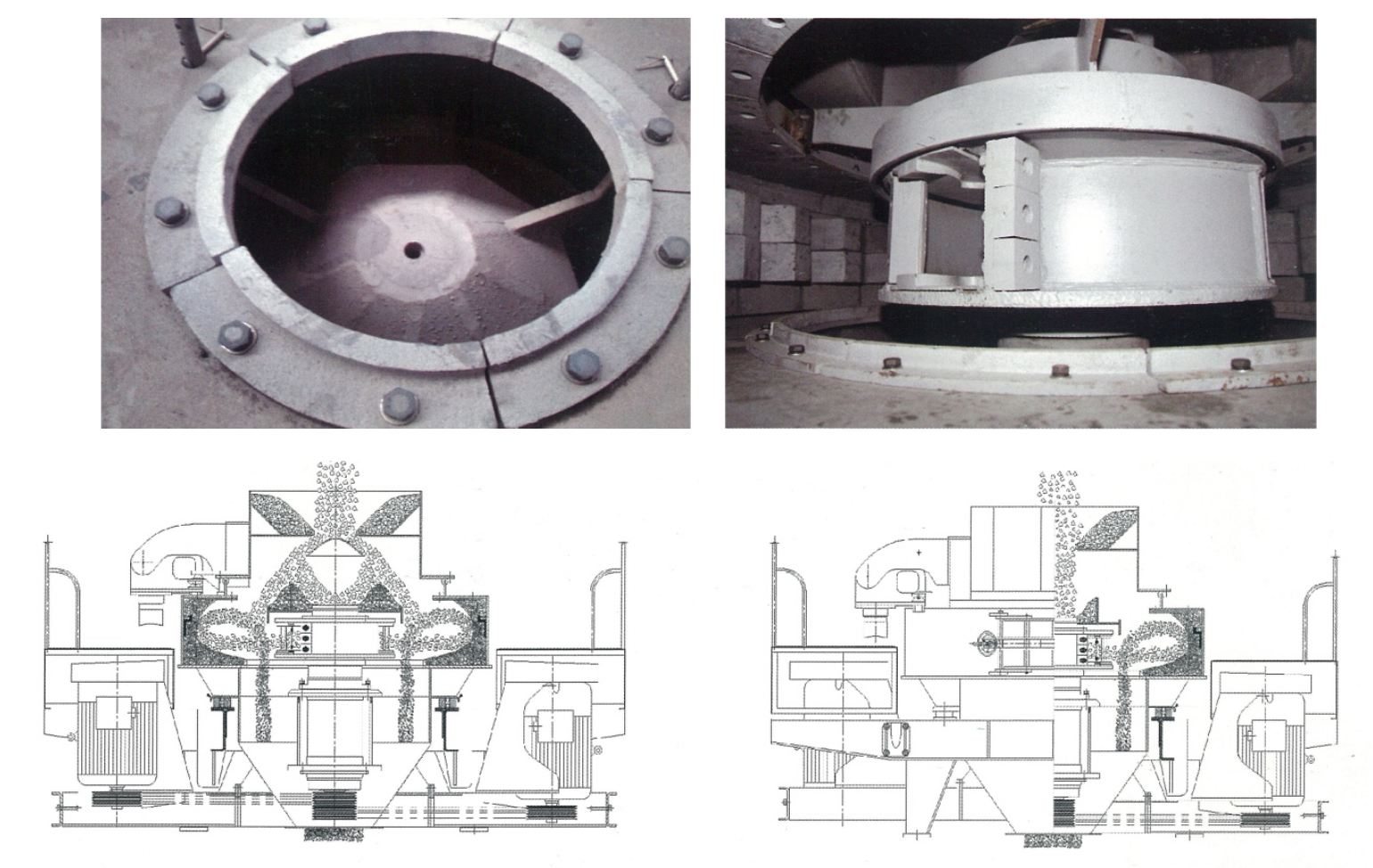

VSI Series Sigh Efficiency Vertical Shaft Impact Crusher

VSI series high-efficiency vertical shaft impact crusher is the result of the latest design by German authoritative experts combined with the working conditions in China, and is the exclusive high-performance sand making equipment with world advanced level. The machine is specially designed to provide high-quality stone aggregate for highway, high-speed railroad, high-rise building, municipal engineering, hydropower dam construction, concrete mixing plant, and is the preferred equipment in the field of artificial sand making and stone shaping.

Equipment features and technical advantages

1, processing a large number of high output-50-500t/h, compared with the traditional equipment under the same power, the output increased by 30% and stable.

2, low consumption of wearing parts - the best crushing chamber material impact angle design, and less friction with wear parts, compared with the traditional equipment running costs are 40% lower, directly reducing the use of equipment costs.

3, the product has excellent grain shape - the product is cubic, good grain shape, reasonable grading, fineness modulus adjustable; especially suitable for artificial sand making and stone shaping, practice has proved that than other traditional equipment for sand making, shaping effect increased by 30%.

4、Hydraulic device, easy to maintain a hydraulic cover device, so that the internal parts of the crushing chamber can be easily disassembled and replaced, shortening the downtime and saving time and labor.

5、Automatic detection, safe and reliable equipment over vibration display and alarm device, if the equipment occurs bad operation, can issue a warning, so that the equipment stops working, to protect the machine.

6, thin oil lubrication, automatic maintenance of a German original thin oil lubrication station, dual oil pumps complementary to ensure the supply of oil; no oil flow, no oil pressure, automatic shutdown; water-cooled cooling, winter motor heating start.

7、Multi-functional, flexible application - Unique feeding crushing structure, with a variety of crushing cavity type, can easily realize the “stone to stone” and “stone to iron” conversion, thus solving the problem of multi-functional machine. If users want to change the application of VSI crusher, no need to make major adjustments to adapt to the different needs of users: sand making, shaping, abrasive materials, and so on.

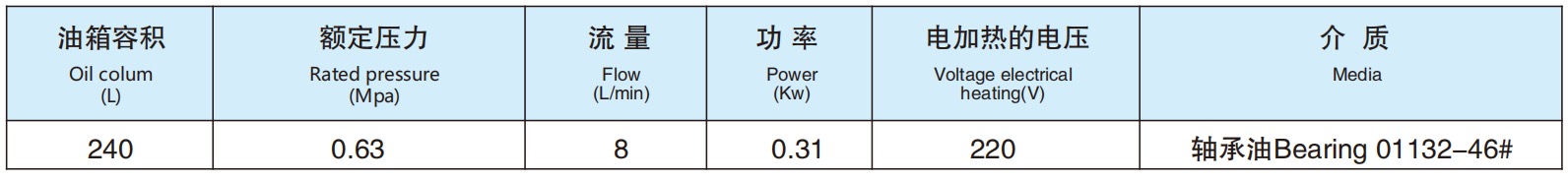

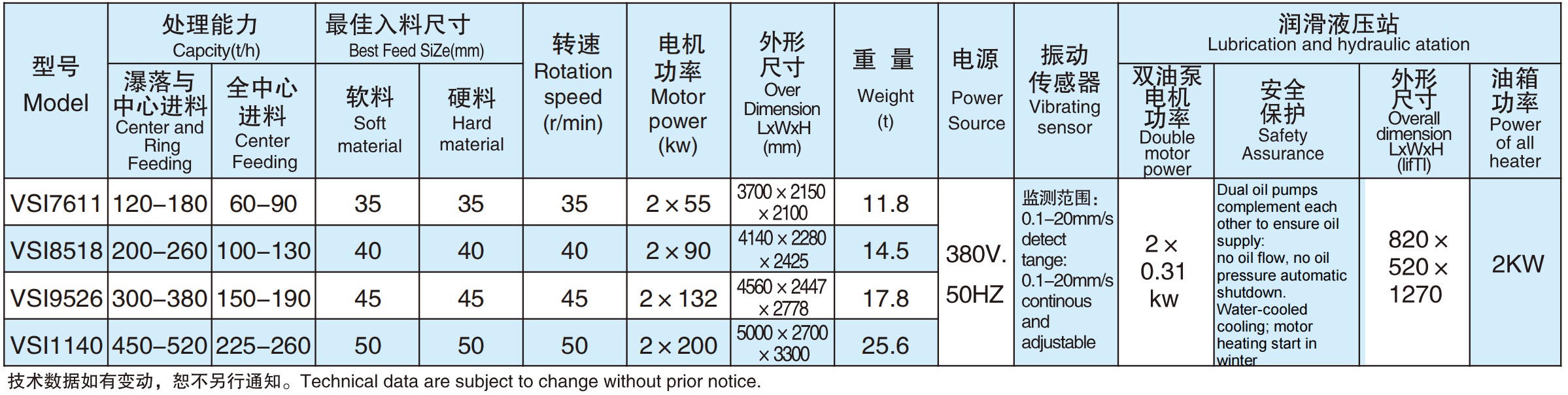

Specifications and performance parameters

Contact: Susie

Phone: +8618026135595

E-mail: info@bomstar-tec.com

Whatsapp:+8618026135595

Add: No.38 Baishandong Street Tonghe Baiyun District Guangdong Province, China

We chat